-

Close

- Home

- Products

- YAMAHA

- YAMAHA FINE TECHNOLOGIES

- HELLER

- MYCRONIC

- MYCRONIC (Axxon Dispenser & Conformal Coater)

- TECHVALLEY

-

PLASMATREAT

- Plasma film systems: Potential - free pretreatment of alumin um foil and plastic films

- Plasma systems for coil coating processes – plasma cleaning without chemicals or waste wate

- Plasma systems for reliable bonding of light - weight panels

- Plasma systems for pretreating profiles made of plastic, alumi num and EPDM

- Plasma robot systems: Complete automation with perfect inline integratio

- Plasmatreat laboratory systems to customize surfaces of plastic, glass or metal

- Plasma technology testing: Openair - Plasma® test systems

- SONOTEK

- NUTEK

- AUROTEK

- STOELTING

- AVIO

- BEAC

- SAWA

- BLACKSTONE-NEY ULTRASONICS

- RETHINK ROBOTICS

- GERMAN ROBOTICS

- PILLARHOUSE

- AEGIS SOFTWARE

- DEN-ON INSTRUMENTS

- Services

- News & Events

- Global Network

- Contact

Filter by

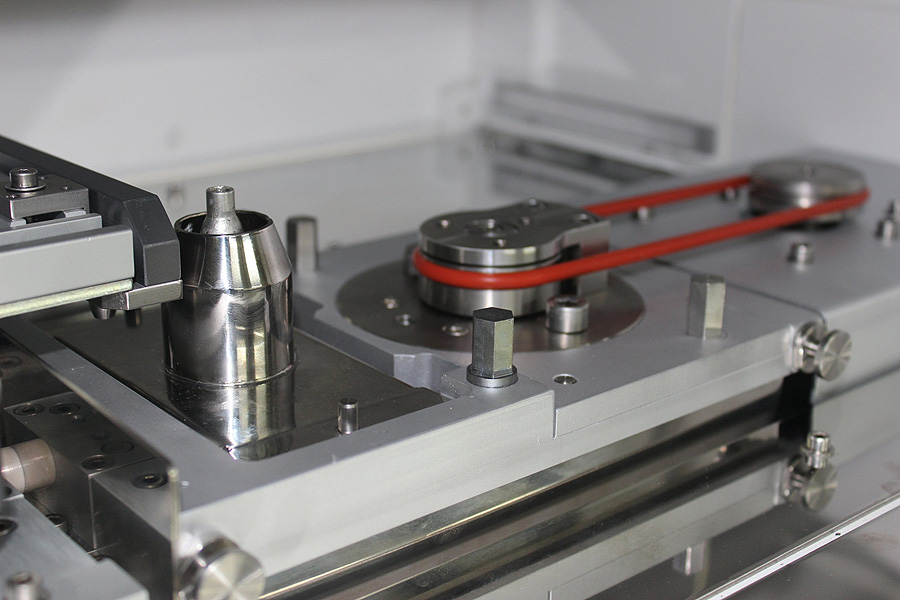

PILOT

PRODUCT DESCRIPTION

Although a low-cost system, the PILOT is offered with the ability to run the acclaimed highly flexible Pillarhouse AP nozzle technology, together with our patented market leading 1.5mm micro nozzle. The process is enhanced by a localised hot Nitrogen environment at the point of soldering. An optional Nitrogen generator is built into the base of the unit and can be used to supply Nitrogen at the required levels, whilst acting as a machine stand.

Designed for low maintenance, the PILOT offers a slide in/out solder bath design for ease of access. This in conjunction with our proven impellor driven pump technology, makes a highly reliable low maintenance system.

By carrying product over the flux, solder and optional preheat stations, the PILOT offers a light, highly accurate X, Y system.

Programming is accessed through the world leading Pillarhouse ‘Point and Click’ PillarCOMM software package. Optional offline programming is available via PillarPAD which allows programs to be generated independently from the machine using Gerber data.

features

- Machine mounted TFT monitor with integral PC

- Inerted Nitrogen system

- Titanium Drop-Jet fluxer

- One AP style solder nozzle tip

- Internal fume extraction

- Manual Fiducial Correction System

- Process Viewing Camera

- Colour programming camera

- Two universally adjustable tooling carriers

- PillarPAD offline programming system

- PillarCOMM LITE – Windows® based ‘Point & Click’ interface

- Solder wave height measurement & correction

- Lead-free compatible

- Day-to-day service kit

specifications

Height

With monitor 1050mm / 42”,

with cowling 750mm / 29” – without 695mm / 27”

Width

With flux bottles 1090mm / 43”- without 915mm / 36”

with solder bath out 1380mm / 54”

Depth

700mm / 28” to 963mm / 38” with keypad tray out

Weight

170kg (table-top format)

Board size

330mm x 250mm / 13″ x 10″

Edge clearance

Above / below 3mm

Height clearance

Above / below 40mm nominal

Solder

Most commonly used solder types – including lead-free

Solder pot capacity

6kg

Applicators

AP style – 2.5mm to 16mm dia.

Extended AP style – 2.5mm to 20mm dia.

Micro nozzle – 1.5mm to 2.5mm

Jet-Tip style – 6mm to 20mm dia.

Special dedicated nozzles available upon request

Flux

Low maintenance Drop-Jet system. Low solids (below 8%), no clean flux, pressurised and inerted system, optional water-soluble system available

X, Y & Z Axis resolution

0.1mm

Repeatability

+/- 0.05mm

Nitrogen usage

30 litres gas/min. 5 bar pressure

Nitrogen purity

99.99% or better

Power supplies

Single phase + PE

Voltage

208V – 250V

Frequency

50/60Hz

Power

4kVA including bottom-side IR preheat

Transport

Hand load

Tooling

Integral adjustable board guides, includes finger extensions and board clamps

Programming

Windows® based PillarCOMM Lite ‘Point & Click’ interface

Promotion Movie

Related Product