-

Close

- Home

- Products

- YAMAHA

- YAMAHA FINE TECHNOLOGIES

- HELLER

- MYCRONIC

- MYCRONIC (Axxon Dispenser & Conformal Coater)

- TECHVALLEY

-

PLASMATREAT

- Plasma film systems: Potential - free pretreatment of alumin um foil and plastic films

- Plasma systems for coil coating processes – plasma cleaning without chemicals or waste wate

- Plasma systems for reliable bonding of light - weight panels

- Plasma systems for pretreating profiles made of plastic, alumi num and EPDM

- Plasma robot systems: Complete automation with perfect inline integratio

- Plasmatreat laboratory systems to customize surfaces of plastic, glass or metal

- Plasma technology testing: Openair - Plasma® test systems

- SONOTEK

- NUTEK

- AUROTEK

- STOELTING

- AVIO

- BEAC

- SAWA

- BLACKSTONE-NEY ULTRASONICS

- RETHINK ROBOTICS

- GERMAN ROBOTICS

- PILLARHOUSE

- AEGIS SOFTWARE

- DEN-ON INSTRUMENTS

- Services

- News & Events

- Global Network

- Contact

Filter by

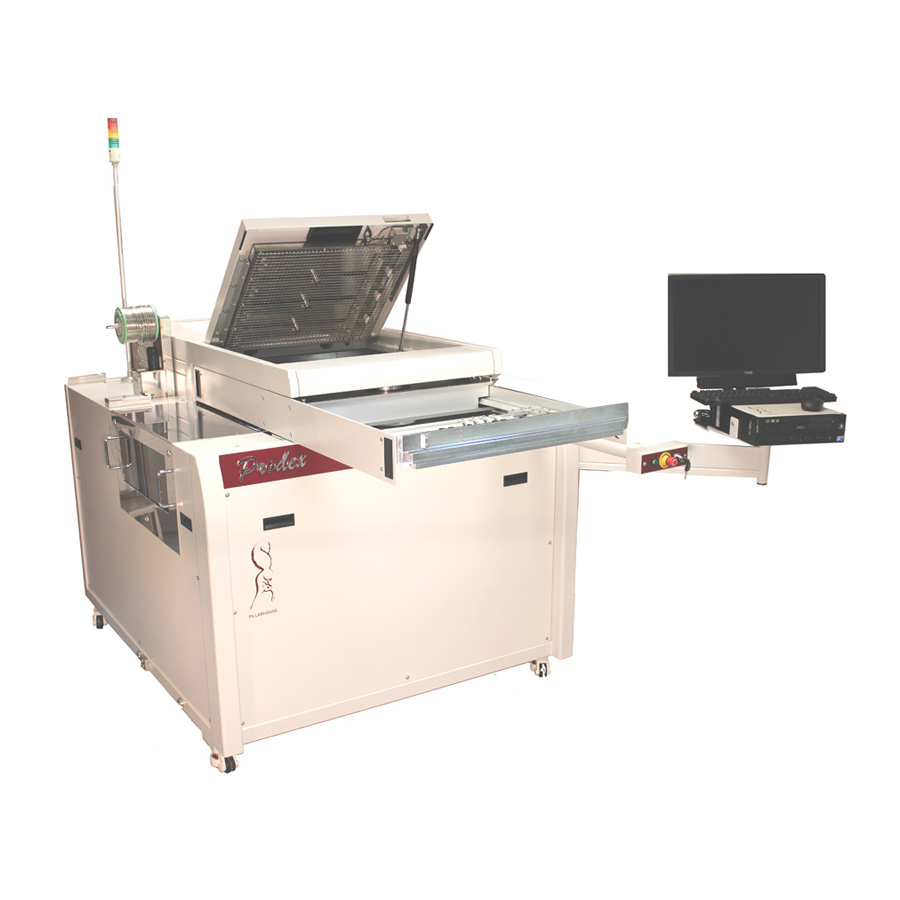

JADE PRODEX

PRODUCT DESCRIPTION

The Jade PRO is configured with twin adjacent solder baths on independent Z axis drives. This achieves increased production flexibility by permitting use of two different nozzle tip sizes which can be allocated as process requirements dictate within any particular area on a PCB.

The Prodex series is controlled by a PC, through PillarCOMM, a Windows® based ‘Point & Click’ interface with a PCB image display.

Additionally our optional PillarPAD offline programming package allows the operator to produce programs independently from the machine using Gerber data.

features

- DC servo drives

- Rotary indexing table with twin adjustable positions

- Integral PC and machine mounted monitor

- Twin solder bath capability on independent Z axis

- Inerted Nitrogen system

- Internal fume extraction

- Titanium Drop-Jet fluxer

- Universally adjustable tooling carrier

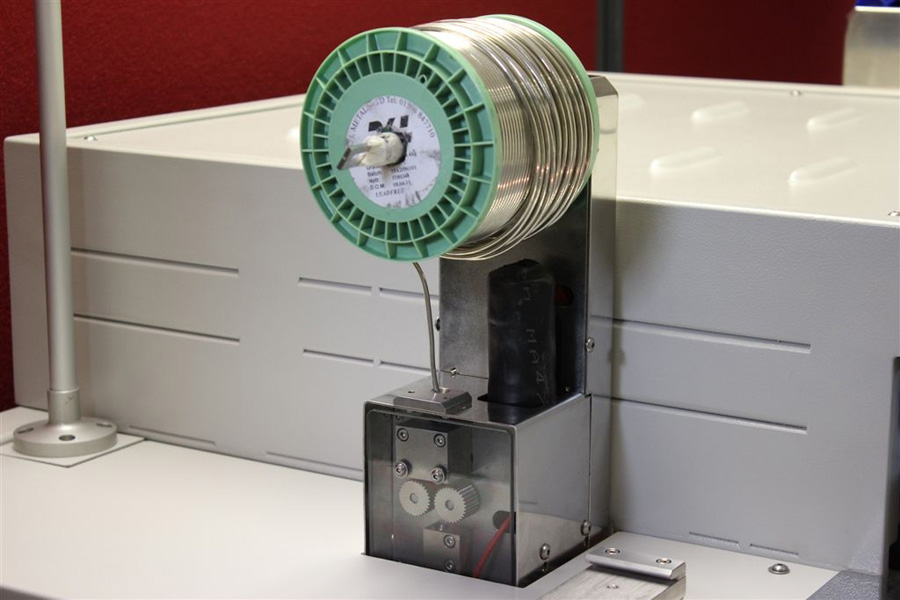

- Auto motorised wire solder feed & level detect

- Solder bath coding – identifies correct bath for program

- Solder wave height measurement and correction

- Set of AP style solder nozzle tips

- Thermal nozzle calibration system using integrated setting camera

- Auto-nozzle conditioning system

- Manual fiducial correction system

- Colour programming camera

- Process viewing camera(s)

- Multilevel password protection

- Light stack

- PillarCOMM Windows® based ‘Point & Click’ interface

- PillarPAD offline programming system

- Lead-free compatible

- Day-to-day service kit

specifications

Height

1208mm / 47.5” to 2025mm / 80”- with light stack

Width

1250mm / 49“ to 1460mm / 57”- with rotate

Depth

2020mm / 79.5”

2240mm /88” with flux bottles

Board size

457mm x 508mm / 18”x 20”

Edge clearance

Above/below 3mm

Height clearance

Above/below 40mm nominal

70mm max. top-side only

Solder

Most commonly used solder types – including lead-free

Solder pot capacity

20kg standard – 30kg large bath

Applicators

AP style – 2.5mm to 16mm dia.

Extended AP style – 2.5mm to 20mm dia.

Micro nozzle – 1.5mm to 2.5mm

Jet-Tip style – 6mm to 40mm dia.

Jet-Wave nozzle – up to 25mm width

Special dedicated nozzles available upon request

Flux

Low maintenance Drop-Jet system. Low solids (below 8%), no clean flux, pressurised and inerted system, optional water soluble system available

X, Y & Z Axis resolution

0.1mm

Repeatability

+/- 0.05mm

Nitrogen usage

Up to 40 litres gas/min per bath with standard AP solder nozzle, 5 bar pressure.

Refer to Pillarhouse for Nitrogen usage requirement with dedicated multi-tube nozzle assemblies.

Nitrogen purity

99.995% or better

Power supplies

Three phase + neutral + PE

Voltage

230 V phase to neutral / 400V phase to phase

Frequency

50/60Hz

Power

Maximum 9kVA per phase machine configuration dependent

Transport

Hand load

Tooling

Integral adjustable board guides, includes finger extensions and board clamps.

Programming

PillarCOMM Windows® based ‘Point & Click’ interface

Promotion Movie

Related Product