-

Close

- Home

- Products

- YAMAHA

- YAMAHA FINE TECHNOLOGIES

- HELLER

- MYCRONIC

- MYCRONIC (Axxon Dispenser & Conformal Coater)

- TECHVALLEY

-

PLASMATREAT

- Plasma film systems: Potential - free pretreatment of alumin um foil and plastic films

- Plasma systems for coil coating processes – plasma cleaning without chemicals or waste wate

- Plasma systems for reliable bonding of light - weight panels

- Plasma systems for pretreating profiles made of plastic, alumi num and EPDM

- Plasma robot systems: Complete automation with perfect inline integratio

- Plasmatreat laboratory systems to customize surfaces of plastic, glass or metal

- Plasma technology testing: Openair - Plasma® test systems

- SONOTEK

- NUTEK

- AUROTEK

- STOELTING

- AVIO

- BEAC

- SAWA

- BLACKSTONE-NEY ULTRASONICS

- RETHINK ROBOTICS

- GERMAN ROBOTICS

- PILLARHOUSE

- AEGIS SOFTWARE

- DEN-ON INSTRUMENTS

- Services

- News & Events

- Global Network

- Contact

Filter by

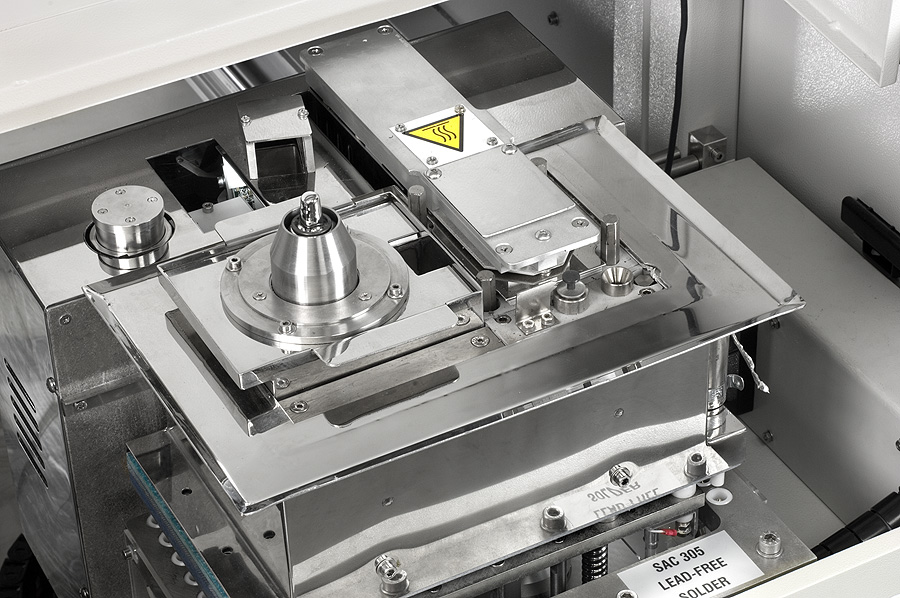

ORISSA SYNCHRODEX

PRODUCT DESCRIPTION

Supplied as standard with our patented design Drop-Jet fluxer, this system offers accurate, controlled flux deposition either prior to or during the optional top side preheat function. Preheat can be controlled via an optional top-side closed loop pyrometer system for optimum temperature profile regulation.

Our low maintenance solder bath and pump mechanism moves in three axes. Solder is applied using our proven technology single point AP nozzle design incorporating patented spiral solder return to bath technology offering increased wave stability with reduced potential for solder balls.

The system can also accommodate our latest generation micro nozzle, together with Jet-Wave, Wide-Wave and dedicated multi-tube single dip solder technology.

As with all Pillarhouse systems, the soldering process is enhanced by a hot Nitrogen curtain which provides an inert atmosphere for the soldering process and also assists in the prevention of oxidation. This process provides a local preheat to the joint thus reducing thermal shock to localised components.

The Synchrodex is controlled by a PC, through PillarCOMM, a Windows® based ‘Point & Click’ interface with PCB image display. Additionally, our PillarPAD offline package allows the operator to produce programs independently from the machine using Gerber data.

features

- In-line motor driven auto width adjust through feed synchronous movement conveyor

- Conveyor side clamping

- Integral PC and machine mounted monitor

- Motorised auto-solder top-up (wire feed) & solder level detect

- Heated inerted Nitrogen system

- Titanium Drop-Jet fluxer

- Set of AP solder nozzle tips

- Internal fume extraction

- Colour programming camera

- Solder wave height measurement and correction

- Pump rpm

- Auto-nozzle conditioning system

- Thermal nozzle calibration system using integrated setting camera

- Windows® based PillarCOMM ‘Point & Click’ interface

- Light stack

- Auto fiducial recognition and correction system

- Flux level sensor

- Multiple level password protection

- PillarPAD offline programming system

- SMEMA compatible

- Process viewing camera with record feature

- Lead-free capability

- Day-to-day service kit

specifications

Height

1615mm / 63” – excluding light stack

Width

813mm / 32“

Depth

2024mm / 80”

Board size

Max. – 457mm x 610mm / 18”x 24”

Min. – 102mm x 102mm / 4”x 4”

Edge clearance

Above/below 3mm

Height clearance

Below 40mm – above 45mm

100mm – upon request

Extraction

Fan: 276mm dia.

Rating

1000m3/hr / 589 CFM

Solder

Most commonly used solder types – including lead-free

Solder pot capacity

15kg standard – 25kg large bath

Applicators

AP style – 2.5 – 16mm dia.

Extended and Jet-Tip nozzles – up to 25mm dia.

Jet-Wave nozzles – up to 25mm width

150mm Wave nozzle

Flux

Low maintenance Drop-Jet system. Low solids (below 8%), no clean flux, pressurised and inerted system, optional water-soluble system available

Flux tank capacity

1 litre

Fluxer speed

50 dots/second

Deposition size

4.0-6.0mm / 0.16-0.24”

X, Y & Z axis resolution

0.15mm

Repeatability

+/- 0.05mm

Nitrogen supply pressure

5 bar / 72 psi

Nitrogen usage

30-100 litres/min. – solder nozzle configuration dependent

Nitrogen purity

99.995% or better

Air supply pressure

5 bar / 72 psi

Air usage

10 litres/min. / 0.35 CFM

Power Supplies

Single phase + PE

Voltage

230V

Frequency

50/60Hz

Power

10.5kVA max. – machine configuration dependent

Transport

Conveyor

Promotion Movie

Related Product